Oil is taken out of the barrel. when this is done, Oil is spilled. This costs you money

Measurement is made. When this is done, Oil is spilled. This costs you money

Oil is poured into the vechicle. When this is done, Oil is spilled. This costs you money

Measurement Errors. This costs you money

* As per study done by TERI (The Energy and Resources Institute). For example if you consume 10 barrels/month your spillage is 63 Ltrs/month.

As per a study by EPA (Environment Protection Agency) 1 Ltr of Oil contaminates 50,000 Ltrs of ground water

Spilled oil is cleaned with cotton waste and this is disposed in the dust bin. This trash is

sent to the dump yard(oil is not degradable), and when it rains, the water mixes with oil and seeps into the ground, when you wash the floor the oil gets into the sewer

Similarly for packed oil (This is more damaging, the extra oil is given to the customer and most of the time the customer dumps it in the dust bin)

(Just imagine the damage by using packed oil)

Do not bury it

Do not throw it in the trash

Do not pour it down the drai

Do not throw it on the ground

Do not dump it down the sewer

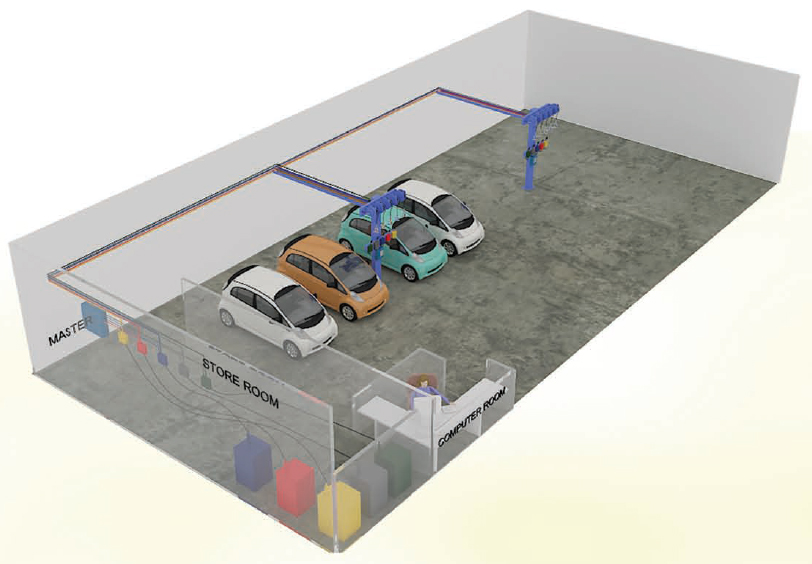

For every transaction the technician is required to go to the store get oil.(Or oil cans) It takes a minimum of 15 to 20 min. This costs you money

Some times he is waiting for the Delivery or gossiping

For example in your workshop ,oil change is done in 45 vehicles /day

Then 45 x 20 minutes = 900 minutes is lost

This is equivalent to 2 Man days. i.e 2 persons salary/month

Salary of each technician is Rs.5000=00,Then loss is Rs.10000/month

If each technician services 3 cars/day , Average income per car is Rs.500

Then 2 technicians service 6 cars/day, Income per day lost is Rs.3000

Income Lost per month ( 25 working days) =25 x 3000 = Rs.75000/month

Convert All your losses Into Profits by installing Protech Computerised integreted Moduler Network based Oil Dispensing and Management System

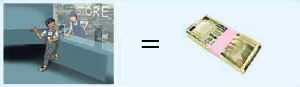

Computerised oil dispenser is microprocessor based modular , Networked based metered oil Dispensing system using cutting edge technology

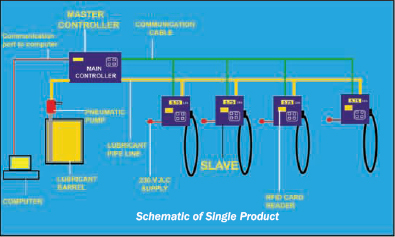

It uses one metering Unit (for each product) for multi point dispensing with master-slave concept. The master contains the metering unit and is networked with slaves at the point of dispensing(at the bays of the workshop), Each master can handle up to 50 slaves (i.e. 50 dispensing points) and up to 5 products. The required quantity can be programmed at the slave or sent from the fluid management software. The message is sent to the master which in turn takes charge of that particular slave and dispenses the programmed quantity through that slave only. The master is connected with a pneumatic pump which can be directly mounted on the barrel.

The Master is a microprocessor based system. It consists of an RS- 485 Communication Port, Oval Gear meters for metering each product with great accuracy, built in calibration, Totalizer (for better accountability), a backlit LCD display, memory to store 1000 transactions & a keypad(keys are life time warranty). It has an inbuilt barrel empty indicator, port for communication with PC (Where in the Data can be downloaded).

The slave is a microprocessor based system. It consists of an RS-485 communication Port, Backlit LCD display, oil low level indicator, keypad(keys are life time warranty), job card entry, RFID Reader 4 keys, a status indication lamp to indicate the availability of the master and a Non drip nozzle.

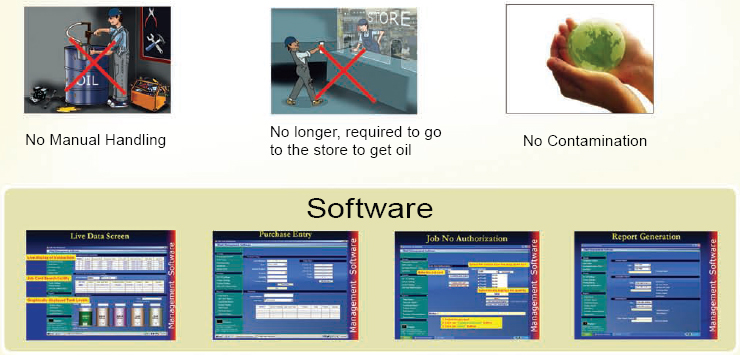

The lube management software helps in keeping drop to drop accountability and comprehensive records of all transactions. It enables the workshop manager to have control over bulk oil usage to prevent oil loss.