AL-96 THE SYSTEMATIC APPROACH TO SINGLE POINT LUBRICATION:

Grease Lubrication are critical parts of maintenance in any industrial operation. Proper Lubrication can reduce equipment's down time and lost

labour hours, as well as give the equipment longer life. Why take chances with lubrication? AL-96 eliminates the guess work.

How AL-96 GREASE FEEDERS CAN SAVE YOUR MONEY:

Almost half of all bearing failures are due to improper lubrication. Overgreasing and under-greasing are eliminated by specially designed flow

control system of AL-96 automatic lubricator. You can save in four ways: fewer replacement bearings, less down time for bearing replacement, less grease used and fewer man-hours spent re-lubricating.

Since the controlled grease flow operates virtually without pressure, under two psi, AL-96 grease feeders also eliminate the danger of blowing the bearing seals which can occur with high-pressure grease guns. Blown or loose seals let lubricating grease leak out, leading to premature bearing failure, as well as possible unsafe conditions and unscheduled down time.

When the AL-96 units require filling with increasing frequency, they can act as an early warning system of potential bearing problems.

If your equipment must be shut down for lubrication service, the time span between services can be increased substantially by installing AL-96 grease feeders. It's easier to schedule planned down time for non-production periods.

Less down time = More production.

AL-96 help maintenance personnel do a more efficient job by taking the guess work out of lubrication. The see-through reservoir of the AL-96 unit tells you when to refill. Preventing even one unnecessary equipment shut down can save many times more then the cost of a AL-96 Unit. Your preventive maintenanace programme is more effective with AL-96 on the job! AL-96 Never forgets!

HOW AL-96 GREASE FEEDERS WORK TO PREVENT OVER AND UNDER LUBRICATION:

There's no way you can see what's going on inside bearings, bushings, pillow block and sleeves. Thats why you can only guess when and how much to

grease. There are times when bearings don't get grease when they need it, or even worse, they get grease when they don't need lubrication.

With AL-96 your bearing get the proper amount of lubrication as needed. When equipment is not operating, there is no grease demand, no over

greasing and no under-greasing. Almost like an insurance policy on lubrication. and with the transparent reservoir, you can see that grease is

available and is being fed to the bearing. The capacity of Al-96 is 65mi.

Grease is discharged from the AL-96 base to the bearing (or bushing) at minimum Pressure values (Usually less than two psi) to protect equipment and yet be adequate to deliver grease. The Bearings natural venturi (Vacuum) action causes the grease to gradually flow to the bearing. This allows the bearing to use grease only as when required. Grease is never forced or packed into the bearing, when the bearing or equipment stops, the grease flow stops.

With grease loaded in the AL-96 reservoir, the compressed coil spring exerts a balanced pressure against the piston connected to the metering rod.

Graduated channels in the metering rod change the discharge orifice area proportional, to the decreasing spring pressure. Thus as the grease flows from the unit and the piston moves downward, the orifice automatically enlarges to maintain a constant discharge pressure. Three spring sizes are available to match optimum discharge pressure to grease viscosity. (Please specify the grade of grease, for proper spring size, while placing the order, or see spring selection guide).

Adaptors are available in thread sizes from M3 to M20 & BSP 1/8", 1/4", 3/8". Other sizes can also be supplied on request

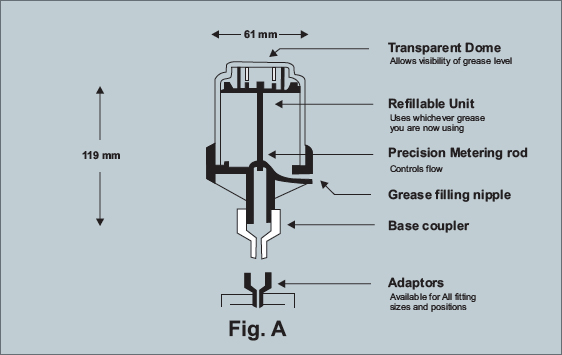

Installation of AL - 96 is simple. All you have to do is choose a suitable adaptor and mount it on the grease filling inlet of the bearing i.e. at the grease nipple. (See Figure A).

| Operating Temperatures From To |

No.0 Grease | No.1 Grease | No.2 Grease | No.3 Grease | No.4 Grease |

|---|---|---|---|---|---|

| -10oc 4oc |

Blue | Silver | Silver | Red | --- |

| 4oc 40oc |

Blue | Silver | Silver | Red | Red |

| 40oc 90oc |

Blue | Blue | Silver | Silver | Red |

| 90oc 120o |

--- | Blue | Blue | Silver | Red |

For the spring size you need to know the operating temperature and the grease weight. For example, if the operating temperature of the bearing ranges from 10°C to 39°C and you are using No.2 grease, then you'll need a silver spring.

Refill ratio of AL-96 compared to normal hand lubrication is 6:1